Welcome to

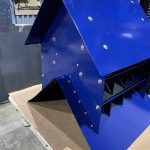

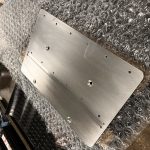

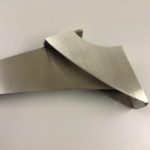

Fabrication

With our extensive range of fabrication services, Wards Welding is able to manufacture a wide variety of steel and metal products to suit all requirements. Using our saws, drills and presses, Wards can deliver the most effective metal processing solution for the jobs at hand. Utilising a variety of manual and CNC machinery, we can handle both one-off fabrication projects and large-scale production runs. Through the use of CAD design, we are able to quickly and effectively interpret the most complex projects and ensure accuracy and repeatability across repeat orders.

Working with projects ranging from a few kilograms to many tons, Wards Welding provides reliable and professional metal fabrication in the UK for clients across multiple industries.

Services:

Sawing | Drilling | Laser | Plasma | Punching | Folding | Bending

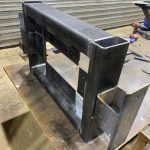

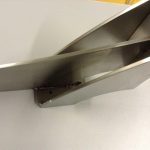

Welding

With our extensive welding capabilities, Wards Welding delivers high-quality results across a wide variety of fabrication projects. Using both MIG and TIG welding processes, our skilled team ensures strength, precision and consistency every time. Whether it’s a one-off prototype or a large production run, we provide accurate, repeatable welds while maintaining the highest standards of workmanship. Through the use of CAD design and custom jigs, we can quickly and effectively interpret the most complex welding requirements and guarantee repeatability on future orders.

Working with projects ranging from light materials to heavy structural steel, Wards Welding is a trusted partner for professional welding services in the UK.

Services:

Sawing | Drilling | Tapping | Welding | Folding And Rolling | Rivnut Instillation | CNC Milling / Turning | 3D Printing

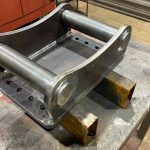

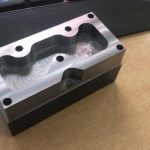

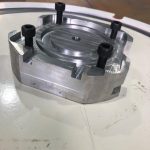

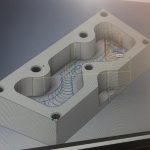

CNC Machining

With our extensive range of CNC machining services, Wards Welding is able to machine and manufacture a wide variety of precision components and parts to suit all of your needs. Using our CNC milling machines, CNC lathes, and drilling equipment, Wards can deliver the most effective machining solution for the jobs at hand. Utilising both manual and CNC equipment, we can handle one-off prototypes as well as large-scale production runs. Through the use of CAD and CAM software, we are able to quickly and effectively interpret the most complex projects and ensure accuracy, consistency, and repeatability across repeat orders.

Working with projects ranging from small precision parts to large-scale machined components, Wards Welding provides trusted CNC machining in the UK for industries of all sizes.

Services:

Tapping | Boring | Reaming | Milling | Turning | Drilling | Engraving | Thread Milling | CAD CAM

3D Printing

With our advanced 3D printing services, Wards Welding is able to produce a wide variety of custom parts, prototypes, and components to suit all of your needs. Using our range of industrial 3D printers and specialist materials, Wards can deliver the most effective on-demand manufacturing solution for the jobs at hand. Utilising a variety of high-performance filaments, from PLA and PETG to carbon fibre reinforced plastics, we can provide both one-off prototypes and large-scale production runs. Through the use of CAD and digital design, we are able to quickly and effectively interpret the most complex projects and ensure accuracy and repeatability across repeat orders.

Working with projects ranging from small intricate components to large functional parts, Wards Welding is your trusted partner for professional 3D printing in the UK.

Services:

Prototyping | Large Quantities | Design Work | 350 x 350 x 350mm

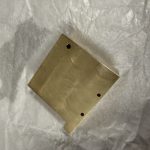

Finishing Services

Hot-Dip Galvanizing – long-lasting corrosion protection for steel structures

Brass & Zinc Plating – durable and decorative metallic coatings

Powder Coating – tough, coloured finishes with excellent resistance

Anodising – protective and decorative coatings for aluminium components

Shot Blasting – surface preparation for coating or restoration

Polishing & Sanding – smooth, consistent finishes for professional appearance